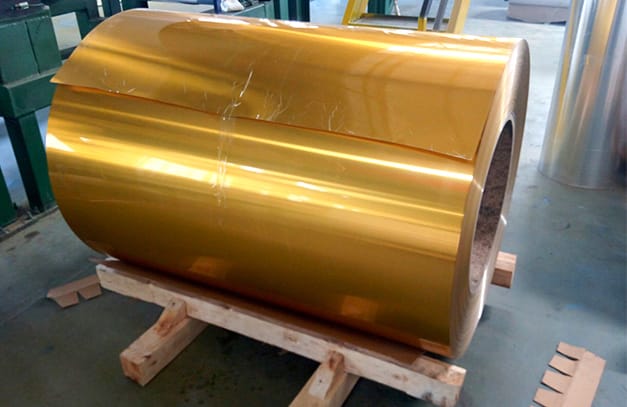

Color Coated Aluminum Coil

Color Coated Aluminum Coil

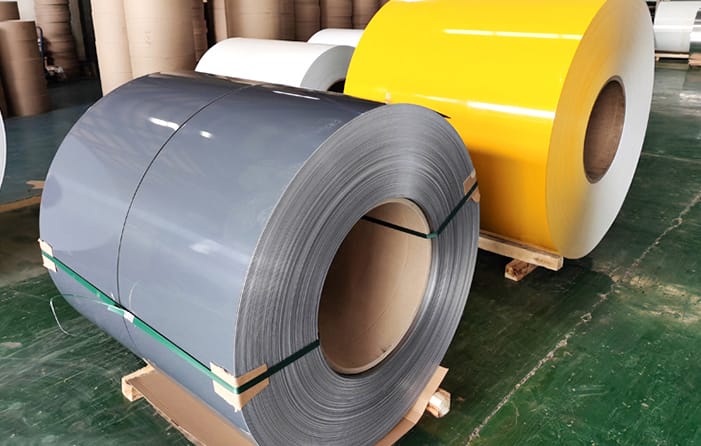

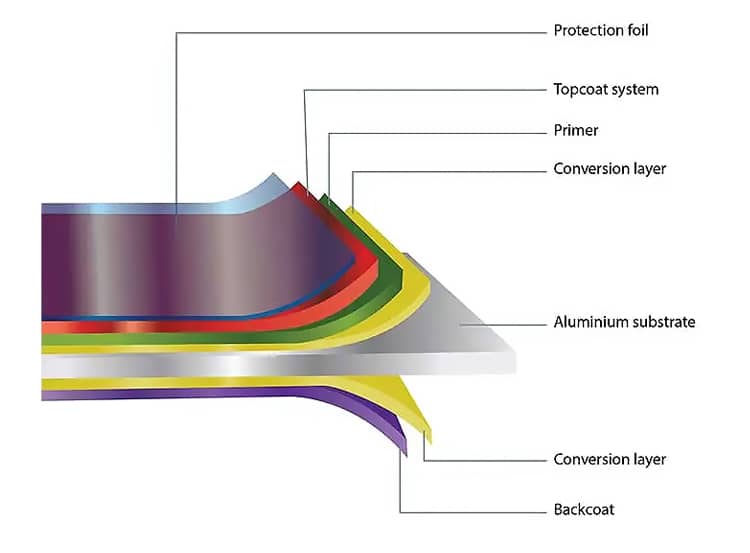

Color coated aluminum coil is a product made of aluminum coil, coated Aluminum coil refers to the aluminum coil through coating and coloring treatment generally includes PE coated aluminum coil and PVDF coated aluminum coil refers to a product with color spraying effect on the surface of aluminum coil, which can also be called color coated aluminum coil.

Available Size Range

0.25mm, 0.30mm, 0.40mm, 0.50mm etc

1240mm, 1270mm, 1520mm, 1550mm,1575mm etc

150mm ,405mm, 505mm, 508mm, 510mm

Coating Thickness:

Front side: ≥ 18 microns (PE), ≥25 microns (PVDF)

Back side:8~10 microns (PE or EP)

Product Specification

| Product Name | Color coated aluminum coil |

|---|---|

| Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006, etc |

| Sample | Provide free samples |

| Material | 1050, 1070, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5754 etc |

| Color | Black, white, blue, red, orange, yellow, rose gold, gray, golden etc |

| Pattern | Wooden grain, stone, camouflage etc |

| Technology | Hot rolled ( DC ), Cold rolling ( CC ), cast |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

| Package | Standard export package,such as wooden box or as required. |

| Satisfy Your Needs | We can customize product specifications, sizes and shapes according to your requirements. |

| Application | Aluminum Roofing,ACP,Roller Shutter Window,Roller Shutter Door,Aluminum Ceiling,Aluminum Grilling, Aluminum Downspout System,Home Appliance’s Plate, body tank of cold chain truck,high speed rail, aluminum pull ring,food packaging,outer packing case of capacitor,external contour of letter channel |

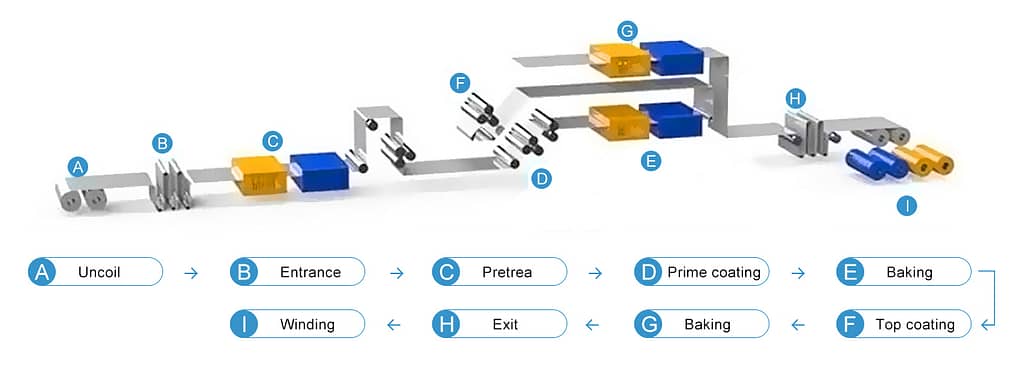

Producing Process

- The input of raw material coil is the continuous uncolling of Uncoler to ensure the continuous and stable input of coll intothe production line. Some adopt cross rotating beam coiler, and some adopt dual sets of alternating uncoilers at the frontand back. In short, it is for timely coil supply.

- Surface cleaning and chemical treatment is to clean the upper and lower surfaces of aluminum coil and carry out chemicalpretreatment to ensure that the paint can be firmly attached.

- For painting, one production line shall have at least two roller coaters to ensure two layers of finish paint and primer.

- It refers to the curing of paint layer, which means that the coil just painted shall complete the fixed ine before contacting thenext roll surface to avoid mutual adhesion and damage. Generally speaking, it includes at least two curing boxes.

- It is the output of finished products to ensure that the production line speed is synchronized with the transfer of finishedproducts.

Coating Type

Silicon modified polyester(SMP): Good abrasion resistance and heat resistance, as well as good external durability and chalking resistance, gloss retention, general flexibility, and medium cost.

High Durability Polyester(HDP): Excellent color retention and anti-ultraviolet performance, excellent outdoor durability and anti-pulverization, good paint film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride(PVDF): Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good mold ability, stain resistance, limited color, and high cost.

PVDF Color Coated Aluminum Coil

PE Color Coated Aluminum Coil

High Durable Color Coated Aluminum Coil

Mirror Color Coated Aluminum Coil

Imitation Stone Coated Aluminum Coil

Wood Grain Coated Aluminum Coils

Transportation

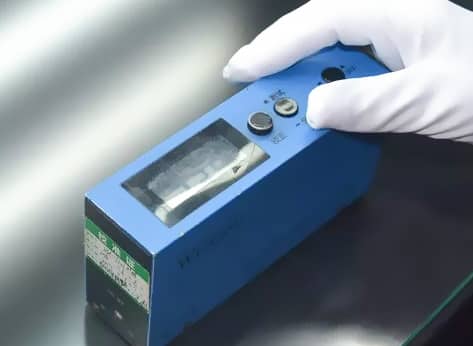

Product Inspection

- We have a new product R&D system and a perfect quality control system to ensure that products leave the factory with zero defects.

- Our color coated aluminum strips will go through strict testing and other processes, and the product quality is recognized by users.

- Our product standards strictly follow: ASTM-B-209M, BS EN 485-2, BS EN 573-3, GB/T3880-2008

- Ultra high corrosion resistance, it can guarantee color fastness for 15-20 years outdoors.

- Good after-sales service.

Looking for the ideal aluminum coil for your industry?

We provide custom solutions to all our customers and offer free Aluminum Coil samples that you can take advantage of.

Advantages of Color Coated Aluminum Coil

√ Corrosion Resistance

√ Durability

√ Lightweight

√ Flexibility and For mability

√ Ease of Maintenance

√ Thermal Reflectivity

√ Customization

√ UV Resistance

√ Cost-Effective

√ Wide Range of Applications

Color Coated Aluminum Coil Workshop

It has two cold-rolled and hot-rolled production lines with an annual out put of 250,000 tons, two pickling production lines with an annual output of 600,000 tons, and three cold-rolled sheet production lines with an annual output of 100,000 tons.

CONTACT US

Call us today for a prompt and competitive quote.